Ukugcina okungaphakathi kwe-Snap Rings yeBores DIN472 GB893 Ukugcina iiRings for Bores - Uhlobo oluqhelekileyo

I-Seeger-Rings ze-shafts kunye nee-bores zezona zinto ziqhelekileyo zokugcina amakhonkco. Ezi makhonkco zibonelela ngesona sisombululo sithandekayo ngokubhekiselele kubukhulu kunye nobubanzi beerali. Bahambisa imikhosi enkulu ye-axial ukusuka kwi-candelo le-mating elikhoyo eludongeni lwe-groove. Amakhonkco angaphandle anakho ukusetyenziselwa isantya esiphezulu sokujikeleza shaft. Isixhobo: I-Phosphated spring iron I-stainless yentsimbi.

Izicelo:

- Imekhenikhali yenjineri

- Ubunjineli bezithuthi

- Iinkqubo zeear

- Injineli yombane

- Ukuchaneka koomatshini

- Isixhobo sobunjineli

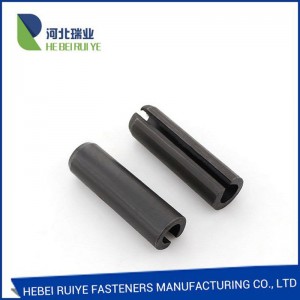

Imijikelezo esuka ku-Hebei Ruiye ihlala isetyenziswa njengezinto zokugcina izinto zebhola. Xa zisetyenziselwa oku zinokuvezwa kwimikhosi enzima. Iijikelezi zifakwe kwii-grooves ezisikwe kwii-shafts okanye kwii-bores. I-DIN 471 i-circlips zezi shafts, i-DIN 472 isetyhula yeyamabhakethi. Iisetyhula zenziwe kusetyenziswa isiphawuli seesekethe. Nawaphi na amandla asetyenziswa licandelo lomatshini adluliselwa kudonga lomgaqo. Iijikelezo zonga imali kunye namaxesha okuseta. I-DIN 472-Ngaphakathi ye-circlip yeyona ndlela iqhelekileyo yesixhobo sokhuseleko seshefts ene-grooves yangaphakathi. Inokuhambisa amandla amakhulu axial avela kwinxalenye yomatshini okhupha amandla kwigreyidi apho isetyhula ifanelekileyo.

Isilumkiso: Ukuhanjiswa kwe-electroplating kwezi mveliso kunokubangela ukwamkelwa kwe-hydrogen

Iinkcukacha Le mveliso kufuneka i-odolwe ngokuphindaphindiweyo engama-5000, izixa ziya kwenziwa kumjikelo njengoko uzifaka.

Ipropathi: elungileyo yokulwa nokudumba kunye neentsimbi zentwasahlobo Zimbini iintlobo: iijikelezo zangaphakathi nangaphandle, ekubhekiswa kuzo ukuba zibekwe emthini okanye emgxeni. Iijikelezo zihlala zisetyenziswa ukukhusela uxhulumaniso lwe-hinged.

Enye iMveliso

Qaphela: kunokwenzeka ukuba utolike amagama ngendlela egwenxa kumhlathi ongaphambili. Ukuyichaza ngenye indlela, umsesane kufuneka ujonge ecaleni ukuze amandla afakwe kwicala elisecaleni lomsesane.

If a snap ring is positioned such that its flat side is pressed into the rounded edge of the groove then when load or force is applied, the flat edge of the snap ring will "bite" into the rounded edge of the retaining groove. The snap ring will distort and ride up the rounded edge, spreading an external snap ring and compressing an internal snap ring. This leaves the clip prone to being forced out of its groove and failure of retaining function. The accompanying images illustrate the correct orientation of the snap ring in its groove.