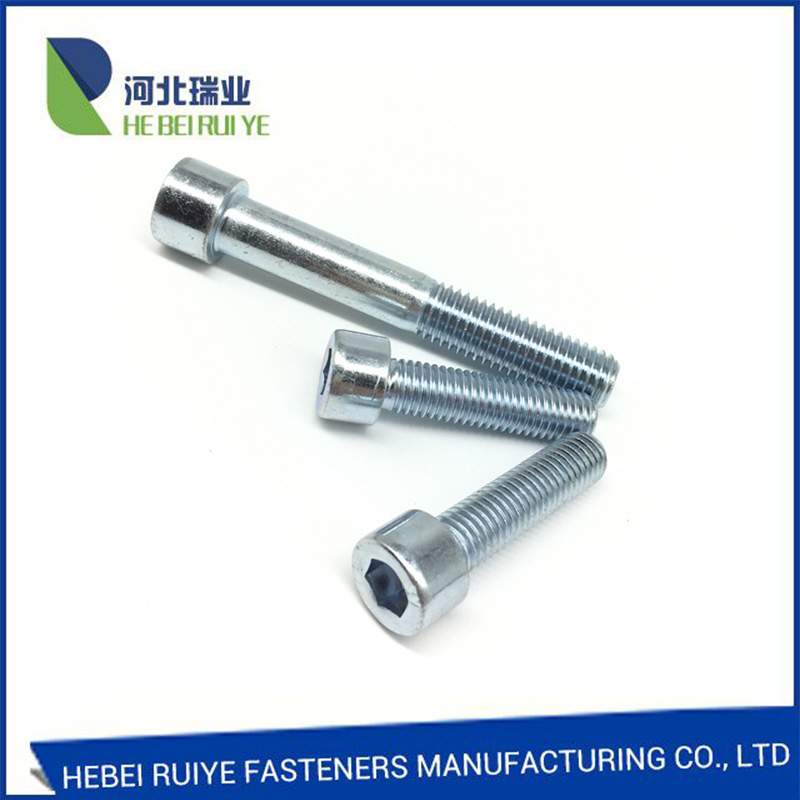

Supply OEM/ODM China Alloy Steel Hex Socket Head Cap Screw DIN912 High Tensile Strength Allen Bolt

Our enterprise insists all along the standard policy of "product good quality is base of organization survival; client gratification could be the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff" and the consistent purpose of "reputation to start with, purchaser first" for Supply OEM/ODM China Alloy Steel Hex Socket Head Cap Screw DIN912 High Tensile Strength Allen Bolt, Please send us your specifications and requirements, or feel free to contact us with any questions or inquiries that you may have.

Our enterprise insists all along the standard policy of "product good quality is base of organization survival; client gratification could be the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff" and the consistent purpose of "reputation to start with, purchaser first" for China Socket Head Cap Screw DIN912, Din 912, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Remember to your inquiry for more details or request for dealership in selected regions.

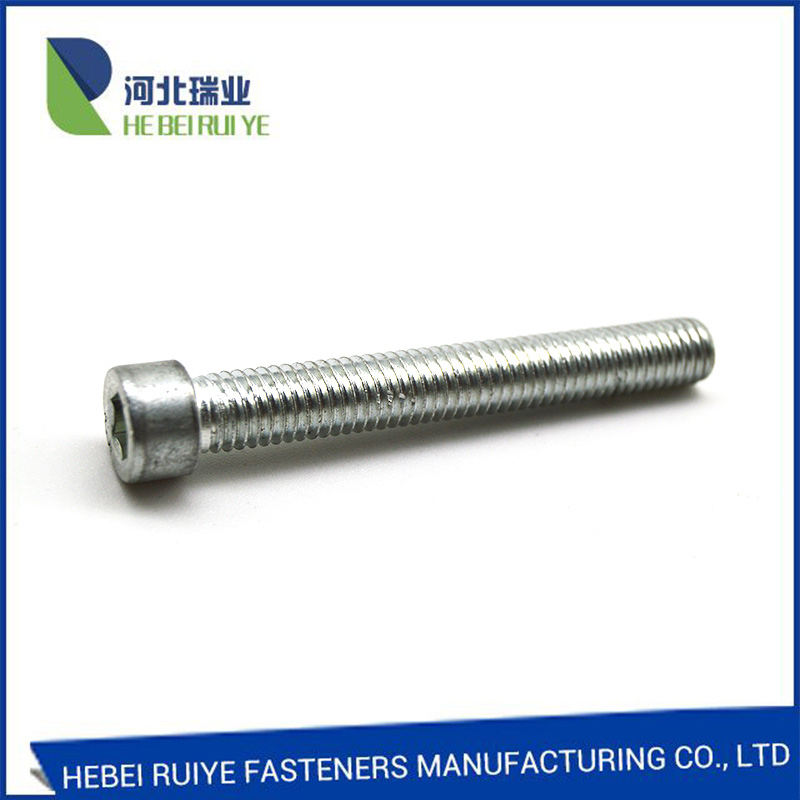

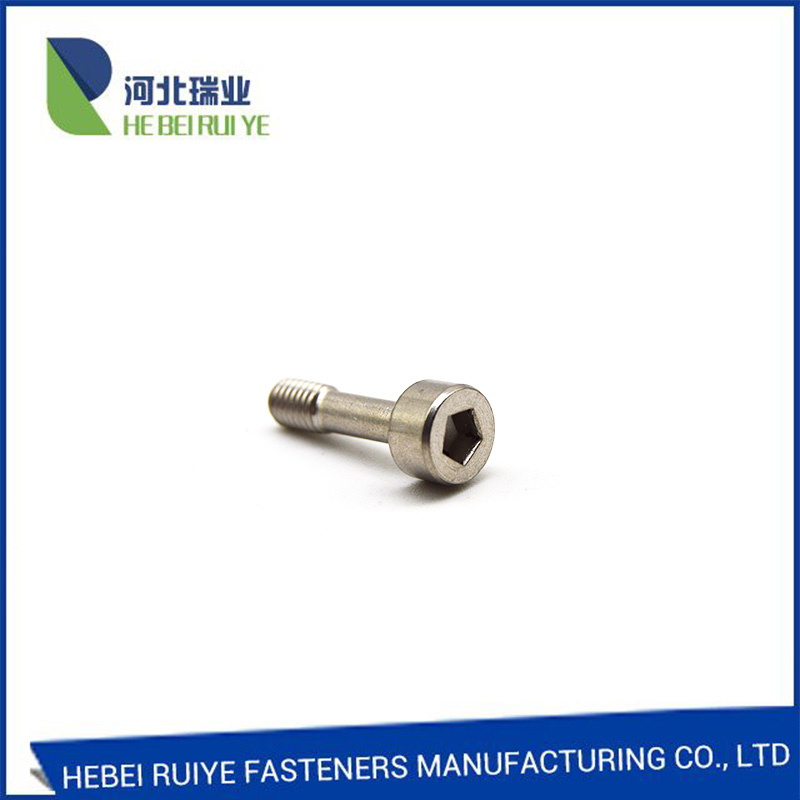

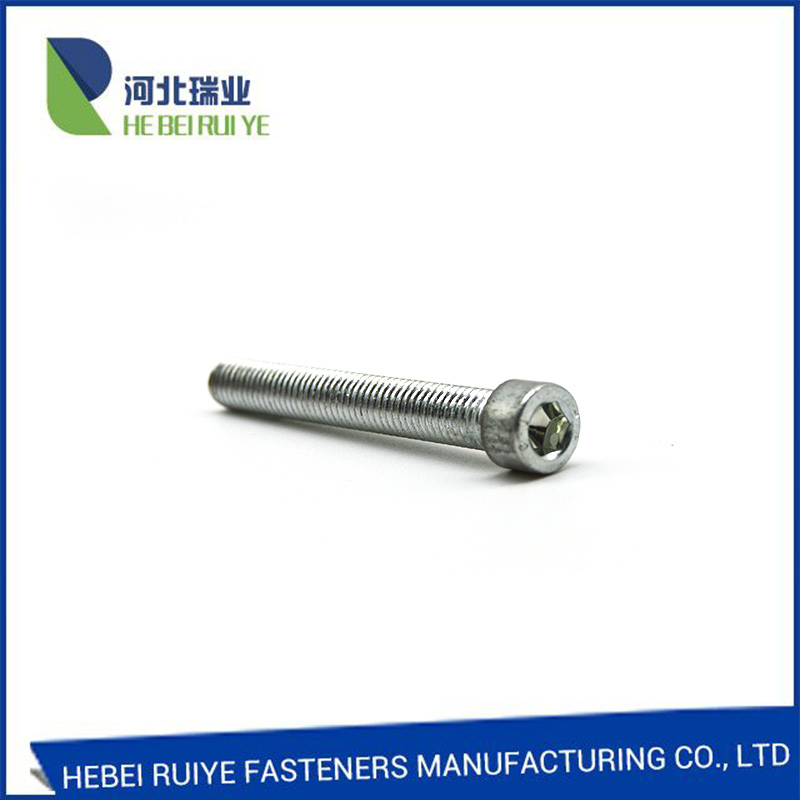

Stainless Steel Socket Head Cap Screw

Product Description

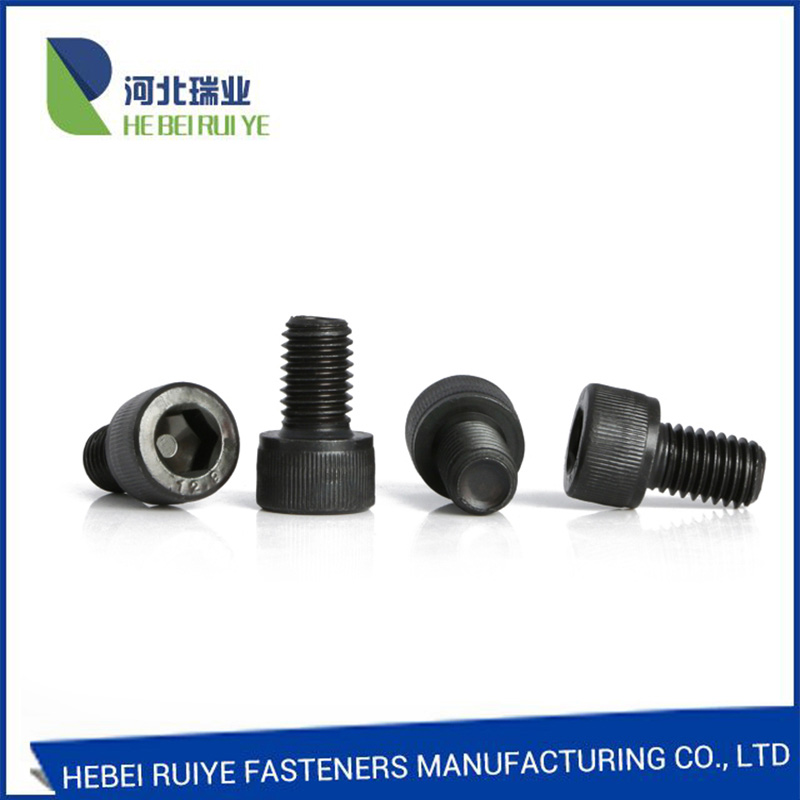

Hexagon socket head screws, also referred to as hexagon socket head bolts, cup head screws and hexagon socket head screws, are called differently, but they mean the same. Generally used hexagon socket head screws are 4.8, 8.8, 10.9, and 12.9. Also called hexagon socket screw, also called hexagon socket bolt. Its head is a hexagonal head and also a cylindrical head. There are stainless steel and iron by material. Stainless steel has stainless steel SUS202 hex socket head screws. This is a stainless steel common material. There are stainless steel SUS304 hex socket head screws and stainless steel SUS316 hex socket head screws. According to the strength grade of hexagon socket head screws, iron has 4.8 grade hexagon socket head screws, 8.8 grade hexagon socket head screws, 10.9 grade hexagon socket head screws, and 12.9 grade hexagon socket head screws. 8.8-12.9 grade hexagon socket head screws are called high strength and high grade hexagon socket screws.

Hardness

Hexagon bolts are classified according to the hardness, carrying force, yield strength, etc. of the screw wire, which is the level of the hexagon bolts, and what level are the hexagon bolts. Hexagon bolts of different grades are required to correspond to different product materials. Hexagon bolts all have the following grades:

Hexagon bolts are classified into ordinary and high-strength according to grade strength. Ordinary hexagon socket bolts are grade 4.8, high strength hexagon socket bolts are grade 8.8 or higher, including grades 10.9 and 12.9. Hexagon bolts of grade 12.9 generally refer to knurled, oil-colored black hex socket head screws.

Hexagon bolts for steel structure connection are divided into more than 10 grades, such as 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, etc. The bolts of grade 8.8 and above are made of low carbon alloy steel or medium carbon steel. After heat treatment (quenching, tempering), they are commonly referred to as high-strength bolts, and the rest are commonly referred to as ordinary bolts. The bolt performance grade label consists of two parts of numbers, which represent the nominal tensile strength value and yield ratio of the bolt material, respectively.

Crafting Process

1. Drill holes according to the diameter of the other hexagon socket until required.

2. Use a cold heading machine to scoop out the inner hexagon.

3, a single piece can be hexagonal punch, punch out with a hammer.

Use

Similar to the countersunk head screw, the nail head is embedded in the machine, and the connection strength is strong, but the hexagonal wrench of the corresponding specification must be used to install and remove the screw. Generally used on various machine tools and their accessories.

Product Display