Lisi o Faʻatauga Faʻalotoifale mo Bores DIN472 GB893 Fausia o Pusa mo Bores - Tulaga masani

O sitaili mo paʻu ma vaʻavaʻa o mama sili ona taofiofia. O nei mama e maua ai le tali sili ona lelei e tusa ai ma le lautele ma lautele lautele. Latou te faʻafeiloaʻi malosi tetele mai le mea e tuʻu ai mating i luga o le puipui. O mama mai fafo e mafai foi ona faʻaaogaina mo le maualuga o le maualuga o le faʻavavega o le faasolosolo. Meafaitino: Faʻaputu o le tautotogo uamea Faʻapupiiina tioata le mama.

Talosaga:

- Faiga faʻainisinia

- Inisinia afi

- Faiga faʻaoga

- Faʻatekonolosi

- Faʻamatalaga faʻainisinia

- Inisinia afi

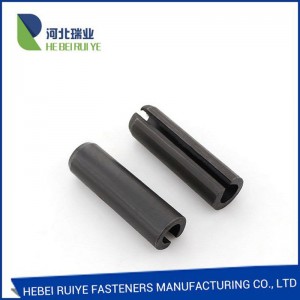

O faʻasalalau mai Hebei Ruiye e masani ona faʻaaogaina e faʻaauau ai elemene mo polo. Pe a faʻaaogaina mo lenei mea e mafai ona latou faʻaalia i malosiaga mamafa. O lapisi vavalalata ua tuʻuina i totonu o togavao ua tipiina i totonu o ni uʻamea po o ni pusa. O le DIN 471 circlips e mo paʻu, DIN 472 circlips e mo fale. Ua fetaui le alalaupapa e ala i le faʻaaogaina o vilivae. Soʻo se malosiaga e faʻaaoga e le masini e tuʻuina atu i le puipui. O faʻatalota e faʻafefe tupe ma taimi faʻatulagaina. O le DIN 472-O le faʻasalalau i totonu o le mea sili ona taatele o le saogalemu mo masini mo faʻamau i totonu. E mafai ona tuʻuina atu malosi malosi mai le vaega o le masini lea e faʻamalosi ai le malosi i le laina lea e fetaui ai le lapisi.

Lapataiga: o le filifilia o nei oloa e mafai ona mafua ai le faʻaaogaina o le hydrogen

Auiliiliga O lenei oloa e tatau ona faʻatulagaina i le tele o le 5000, o le aofaʻi faʻasolosolo aoe faʻaopopoina.

Meatotino: o le malosi o le faʻamaʻi faʻamalosi ma le faʻaaogaina o le uʻamea o le punavai ma le mama o le tautotogo o se filifiliga tau tupe ma le malosi lelei. O le faʻamaunuʻu uliuli-faʻapipiʻi, o le soli faʻamalosi o le pala i totonu o nofoaga malulu. I le siosiomaga malulu, o faʻamaʻi samasama-chromate paʻu ua maeʻa ona i ai le malosi o le pala, ma le sinasina chromate paʻu ua maeʻa ua i ai le teteʻe lelei o le palapala. E lua ituaiga: i totonu ma fafo o le taamilosaga, faʻasino pe o loʻo faʻatutuina i totonu o se fagu po o totonu o se pa. O faʻasalalau e masani ona faʻaaogaina e faʻapipiʻi ai fesoʻotaʻiga.

Isi Mea

Manatua: e mafai ona faʻamatala sese upu i le parakalafa muamua. Ina ia taʻua se isi auala, o le mama e tatau ona faʻalauteleina ina ia faʻaaogaina le malosi i le itu lautele o le mama.

If a snap ring is positioned such that its flat side is pressed into the rounded edge of the groove then when load or force is applied, the flat edge of the snap ring will "bite" into the rounded edge of the retaining groove. The snap ring will distort and ride up the rounded edge, spreading an external snap ring and compressing an internal snap ring. This leaves the clip prone to being forced out of its groove and failure of retaining function. The accompanying images illustrate the correct orientation of the snap ring in its groove.