OEM Supply Iso/en/din127 B Standard Spring Washers

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for OEM Supply Iso/en/din127 B Standard Spring Washers, We've been sincerely searching forward to cooperate with prospects all over the environment. We imagine we are able to satisfy with you. We also warmly welcome consumers to go to our manufacturing unit and purchase our solutions.

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Din 127 Spring Washer, Disc Spring Washer, Spring Washer, Our company is an international supplier on this kind of merchandise. We offer you an amazing selection of high-quality items. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To deliver the best products and solutions and service to our customers at the lowest prices possible.

Product Description

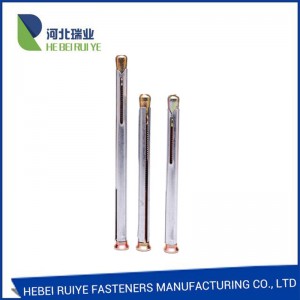

| Product name | DIN127 steel spring washers spring lock washers |

| Size | M2-M30, can be customized |

| Standard | ISO,GB,DIN,BS,ANSI, JIS,Nonstandard |

| Grade | 4.8/ 6.8/ 8.8/ 10.9/ 12.9 |

| Available Material | 1. Stainless Steel: SS201, SS303, SS304, SS316, SS410, SS420 |

| 2. Steel: C45(K1045), C46(K1046), C20,etc. | |

| 3. Brass: C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200CuZn37), C28000(CuZn40),etc. |

|

| 4. Bronze: C51000, C52100, C54400, etc. | |

| 5. Iron: 1213, 12L14, 1215, etc. | |

| 6. Aluminum: Al6061, Al6063, etc. | |

| 7. Carbon steel: C1006,C1010,C1018,C1022,C1035K,C1045,12L14,etc. | |

| 8. Alloy steel: SCM435,10B21, C10B33,etc. | |

| Surface Treatment | Galvanization,Nickel-plated,Black oxide,Dacromet |

| Advantage | OEM / ODM / customized service provided |

| Quality control | ISO standard,100% Whole range inspection through the production |

| Certificate | ISO9001:2008,ISO14001:2004 |

| After-sales Service | We will follow up every customer and solve all your problems satisfied after sales |

Spring washer:

The spring washer is installed under the nut to prevent the nut from loosening.

Spring washers are used to prevent loosening. Flat washers have no anti-loosening function. Flat washers only increase the contact area.

The flat pad is just to increase the contact area, and the spring pad can prevent loosening. For example, the bolt connecting the motor and the base is generally added with a spring pad, because if the motor vibrates without the spring pad, the nut will loosen and the fastening on the equipment with vibration is generally There are spring gaskets on the parts, and generally no gaskets are required on the flange! The addition of spring gaskets on the flange is related to the medium flowing through the pipeline. If pulses are easy to produce, it is best to add spring gaskets, as well as high speed. Fluids, calibers change frequently. Don't generalize. On some valves, stuffing box gland flanges need spring gaskets. Spring gaskets are included in Quick, Easy, and Optimal Selection.

The flat pad is used to increase the fastening contact area. The spring pad is used for places with vibration to prevent loosening. There is no spring washer for fastening PVC flanges. The flat pad is to increase the contact area and prevent friction between the bolt and the workpiece; the spring pad is to prevent the vibration from loosening;