Internal kusunga chithunzithunzi mphete kwa Bores DIN472 GB893 kusunga mphete kwa Bores - Normal Mtundu

Seeger-mphete pa migodi ndi bores ndi ambiri mphete kusunga. Mphete izi kupereka yankho kwambiri yabwino ndi ulemu kwa makulidwe ndi zozungulira m'lifupi. Iwo kusamutsa mphamvu zazikulu ofananira ku chigawo ili mating pakhoma poyambira. The mphete kunja Angagwiritsidwenso ntchito ndi apamwamba kutsinde imathamanga rotational. Zakuthupi: Phosphated masika zitsulo Bright zosapanga dzimbiri.

Mapulogalamu:

- Ukachenjede wazitsulo

- Automotive zomangamanga

- kachitidwe zida

- zamagetsi

- mwatsatanetsatane zimango

- zida zomangamanga

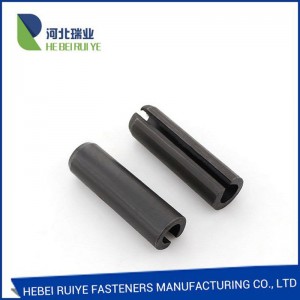

Circlips ku Hebei Ruiye Mankhwalawa amagwiritsidwa ntchito ngati kusunga zinthu kwa mayendedwe mpira. Pamene ntchito imeneyi iwo akhoza poyera kuti mphamvu lolemera. The circlips amaveka mu grooves kusema migodi kapena bores. Din 471 circlips ndi kwa migodi, Din 472 circlips ali bores. Circlips amaveka ntchito pliers circlip. Mphamvu iliyonse ntchito ndi mbali makina ndi kunditumiza ku khoma poyambira. Circlips kupatula ndalama ndi khwekhwe nthawi. The circlip Din 472-Internal ndi ambiri maonekedwe a chipangizo chitetezo cha migodi ndi grooves mkati. Iwo angathe kupatsira mphamvu ndithu ofananira ku mbali ya makina amene ochitachita mphamvu kwa poyambira imene circlip ndi zokuzira.

Chenjezo: electroplating wa mankhwala zikhoza embrittlement wa hydrogen

tsatanetsatane mankhwala ayenera lolongosoka mwa multiples cha 5000, zedi adzakhala adzakhale ngati inu kuwonjezera iwo.

Katundu: wabwino luso odana ndi dzimbiri ndi odana ndi dzimbiri masika zitsulo ndi zitsulo masika mphete ali ndi kusankha ndalama ndi mphamvu wabwino. A wakuda mankwala mapeto ndi modekha dzimbiri zosagwira mu mapangidwe youma. Mu mapangidwe yonyowa, nthaka akumaliza lachikasu chromate yokutidwa ndi kutsutsana dzimbiri, ndipo nthaka chromate yokutidwa akumaliza bwino dzimbiri kukana. Pali mitundu iwiri: circlips mkati ndi kunja, kunena kaya wokwera mu inabala kapena kutsinde ndi. Circlips Mankhwalawa amagwiritsidwa ntchito kuti akalandire kugwirizana kulumikizidwa.

Mankhwala ena

Dziwani: n'zotheka molakwika mawu m'ndime m'mbuyomu. Kunena izo mwanjira ina, mphete ayenera zochokera kuti mphamvu umagwiritsidwa ndi m'mbali mwa mphete.

If a snap ring is positioned such that its flat side is pressed into the rounded edge of the groove then when load or force is applied, the flat edge of the snap ring will "bite" into the rounded edge of the retaining groove. The snap ring will distort and ride up the rounded edge, spreading an external snap ring and compressing an internal snap ring. This leaves the clip prone to being forced out of its groove and failure of retaining function. The accompanying images illustrate the correct orientation of the snap ring in its groove.