Esịtidem retaining snap Mgbaaka maka Bores DIN472 GB893 retaining Mgbaaka maka Bores - Nkịtị Type

Seeger-Mgbaaka maka akụ na bores bụ kasị retaining yiri mgbaaka. Ndị a yiri mgbaaka enye kasị mma ngwọta na-akwanyere ọkpụrụkpụ na radial n'obosara. Ha nyefee nnukwu axial agha si dị mating akụrụngwa n'elu uzo mgbidi. The mpụga yiri mgbaaka nwekwara ike-eji maka dịtụ elu aro rotational gbapụrụ ọsọ. Ihe: Phosphated spring ígwè Bright igwe anaghị agba ígwè.

ngwa:

- Mmụta mekanịkal injinịa

- Automotive engineering

- Gear usoro

- Ọdụdọ engineering

- nkenke arụzi

- ngwa engineering

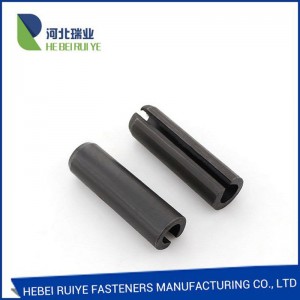

Circlips si Hebei Ruiye na-eji dị ka retaining ọcha maka bọl biarin. Mgbe e ji maka nke a, ha nwere ike gụrụ arọ agha. The circlips na-ruo eruo n'ime grooves bee n'ime akụ ma ọ bụ bores. DIN 471 circlips bụ maka akụ, DIN 472 circlips bụ maka bores. Circlips na-ruo eruo iji circlip ngwa mkpaji. Ọ bụla agha n'ọrụ site igwe akụrụngwa na-agafere na uzo mgbidi. Circlips Echekwara ego na na na ntọlite ugboro. The DIN 472-Esịtidem circlip bụ ihe kasị nkịtị ụdị nchekwa ngwaọrụ akụ na esịtidem grooves. Ọ pụrụ ibufe bukwanu axial agha si akụkụ nke igwe nke na-akpa ike na uzo nke circlip na-ruo eruo.

Ịdọ aka ná ntị: electroplating ndị a na ngwaahịa nwere ike ime ka hydrogen embrittlement

nkọwa Ngwaahịa a ga-iwu na multiples nke 5000, quantities ga-mechie elu dị ka ị na tinye ha.

Property: ọma mgbochi corrosion ike na mgbochi nchara spring nchara na spring ígwè yiri mgbaaka bụ ndị na-echekwa na-ahọrọ ezi ike. A na nwa-phosphate imecha bụ mildly corrosion na-eguzogide ọgwụ na akọrọ gburugburu. Mmiri gburugburu, zinc odo-chromate plated risịrị nwere ụfọdụ corrosion eguzogide, na zinc chromate plated risịrị nwere ezi corrosion eguzogide. E nwere ihe abụọ na ụdị: esịtidem na mpụga circlips, na-ezo aka ma ha na-n'ịnyịnya na a mụụrụ ma ọ bụ na a aro. Circlips na-eji iji nwetara hinged njikọ.

ọzọ Product

Cheta na: ọ bụ ike akọwahie okwu na aga na paragraf. Iji kwuo ya n'ụzọ ọzọ, mgbanaka ga-agba mbọ ka na ike na-etinyere megide ewepụghị n'akụkụ nke mgbanaka.

If a snap ring is positioned such that its flat side is pressed into the rounded edge of the groove then when load or force is applied, the flat edge of the snap ring will "bite" into the rounded edge of the retaining groove. The snap ring will distort and ride up the rounded edge, spreading an external snap ring and compressing an internal snap ring. This leaves the clip prone to being forced out of its groove and failure of retaining function. The accompanying images illustrate the correct orientation of the snap ring in its groove.