Internal ceev Snap Rings rau Bores DIN472 GB893 ceev Rings rau Bores - qub hom

Seeger-Rings rau shafts thiab bores yog cov feem ntau ceev rings. Cov rings muab lub feem ntau dej siab tov nrog rau kev hwm mus thickness thiab radial dav. Lawv hloov loj axial rog los ntawm cov nyob pos tivthaiv mus rau lub zawj phab ntsa. Cov sab nraud rings kuj yuav siv tau rau kuj dua ncej muab speeds. Khoom siv: Phosphated caij nplooj ntoos hlav steel Kaj stainless hlau.

Daim ntaub ntawv:

- Neeg kho tshuab engineering

- Automotive engineering

- Iav tshuab

- Hluav taws xob cov engineering

- Precision mechanics

- Apparatus engineering

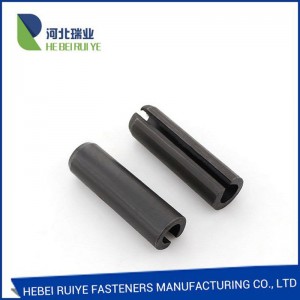

Circlips los ntawm Hebei Ruiye yog feem ntau siv raws li ceev hais txog lub pob bearings. Thaum siv rau qhov no lawv yuav tsum tau raug mus hnyav rog. Lub circlips yog haum rau hauv grooves txiav mus rau hauv shafts los yog bores. DIN 471 circlips yog rau shafts, DIN 472 circlips yog rau bores. Circlips yog ntsuas siv circlip ciaj. Tej rog thov los ntawm lub tshuab tivthaiv yog pauv mus rau lub zawj phab ntsa. Circlips tseg nyiaj thiab teeb lub sij hawm. Lub DIN 472-Internal circlip yog lub feem ntau ntau daim ntawv ntawm kev ruaj ntseg ntaus ntawv rau shafts nrog nrog grooves. Nws muaj peev xwm kis loj axial rog los ntawm ib sab ntawm lub tshuab uas niamntiav tus quab yuam mus rau lub zawj nyob rau hauv uas lub circlip yog haum.

Ceeb Toom: electroplating ntawm cov khoom no tej zaum yuav ua rau hydrogen embrittlement

Paub meej no cov khoom yuav tsum tau txiav txim nyob rau hauv cov zauv ntawm 5000, ntau yuav tsum npawv li koj ntxiv lawv.

Khoom: zoo anti-xeb muaj peev xwm thiab anti xeb caij nplooj ntoos hlav hlau thiab caij nplooj ntoos hlav steel rings yog ib tug yig xaiv nrog zoo zog. Ib tug dub-phosphate finish yog mob me corrosion resistant nyob rau hauv qhuav tej kev kawm. Nyob rau hauv ntub tej kev kawm, zinc daj-chromate plated finishes muaj ib co xeb tsis kam, thiab zinc chromate Plated finishes muaj zoo xeb kuj. Nws muaj ob hom: hauv thiab sab nraud circlips, xa mus rau seb lawv yog mounted rau hauv ib lub bore los yog nyob rau hauv ib tug ncej. Circlips yog feem ntau siv rau kev ruaj ntseg hinged sib txuas.

lwm yam khoom

Nco ntsoov: nws yog ua tau rau misinterpret cov lus nyob rau hauv lub yav dhau los cov pawg lus. Mus rau lub xeev nws lwm txoj kev, lub nplhaib yuav tsum tau taw qhia kom paub li ntawd hais tias cov kev quab yuam yog thov tiv thaiv cov ca sab ntawm lub nplhaib.

If a snap ring is positioned such that its flat side is pressed into the rounded edge of the groove then when load or force is applied, the flat edge of the snap ring will "bite" into the rounded edge of the retaining groove. The snap ring will distort and ride up the rounded edge, spreading an external snap ring and compressing an internal snap ring. This leaves the clip prone to being forced out of its groove and failure of retaining function. The accompanying images illustrate the correct orientation of the snap ring in its groove.