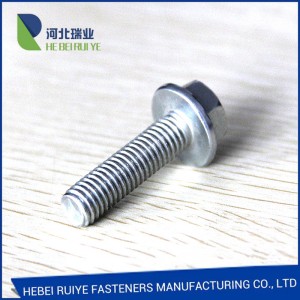

China Wholesale China 3/8″ X 5″ Stainless Hex Lag Coach Bolt Screws 304 (18-8) Stainless Steel DIN571

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for China Wholesale China 3/8" X 5" Stainless Hex Lag Coach Bolt Screws 304 (18-8) Stainless Steel DIN571, Our main objectives are to deliver our clients worldwide with good quality, competitive cost, happy delivery and superb providers.

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for A2 Stainless Steel Coach Screws, China Coach Screws, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We'll keep working hard and offering you the highest-quality goods and service.

Screw:

A screw is a type of fastener, in some ways similar to a bolt , typically made of metal, and characterized by a helical ridge, known as a male thread (external thread). Screws are used to fasten materials by digging in and wedging into a material when turned, while the thread cuts grooves in the fastened material that may help pull fastened materials together and prevent pull-out. There are many screws for a variety of materials; those commonly fastened by screws include wood, sheet metal, and plastic.

A screw will usually have a head on one end that contains a specially formed shape that allows it to be turned, or driven, with a tool. Common tools for driving screws include screwdrivers and wrenches. The head is usually larger than the body of the screw, which keeps the screw from being driven deeper than the length of the screw and to provide a bearing surface.

Wood screw:

Early wood screws were made by hand, with a series of files, chisels, and other cutting tools, and these can be spotted easily by noting the irregular spacing and shape of the threads, as well as file marks remaining on the head of the screw and in the area between threads. Many of these screws had a blunt end, completely lacking the sharp tapered point on nearly all modern wood screws. Eventually, lathes were used to manufacture wood screws, with the earliest patent being recorded in 1760 in England. During the 1850s swaging tools were developed to provide a more uniform and consistent thread. Screws made with these tools have rounded valleys with sharp and rough threads. Some wood screws were made with cutting dies as early as the late 1700s (possibly even before 1678 when the book content was first published in parts).

Once screw turning machines were in common use, most commercially available wood screws were produced with this method. These cut wood screws are almost invariably tapered, and even when the tapered shank is not obvious, they can be discerned because the threads do not extend past the diameter of the shank. Such screws are best installed after drilling a pilot hole with a tapered drill bit. The majority of modern wood screws, except for those made of brass, are formed on thread rolling machines. These screws have a constant diameter, threads with a larger diameter than the shank, and are stronger because the rolling process does not cut the grain of the metal.

Any requirement please contact us.